3D Printed Mouse-trap Cars : 8 Steps with Pictures

Table Of Content

Using ball bearings on the axles really improves the car’s performance. The final principle you need to address is making your car light – this one is pretty intuitive, just don’t make your car too big. The idle wheels need to be as lightweight and frictionless as possible, so small wheels will be used. We are committed to making the impossible stand the test of time, to the highest standards of quality, to help designers and engineers further push the envelope, and to evoke “Wow! "Mercedes designers in Stuttgart could not have designed the M-class," says Mr. Matano. Designworks recently designed the new MCI coach, which he claims is the first new coach design in the U.S. in 25 years.

Mousetrap Cars: How to Build a Fast Racer

One more important concept to think about when selecting wheels for your speed-trap racer is traction. Some times wheel traction can be increased by adding traction treads cut from the center of a rubber balloon (see adding traction treads for more information). Try to copy the design of a top fuel dragster when building a super-fast speed-trap racer. By changing the size of the drive wheel(s) you can speed-up or slow-down your mousetrap vehicle. Larger drive wheels have a greater travel distance per each turn than smaller drive wheel. It would make sense to use a super huge drive wheel so for each turn of this massive wheel the mousetrap vehicle will travel a super huge distance.

Step 4: Competition Day

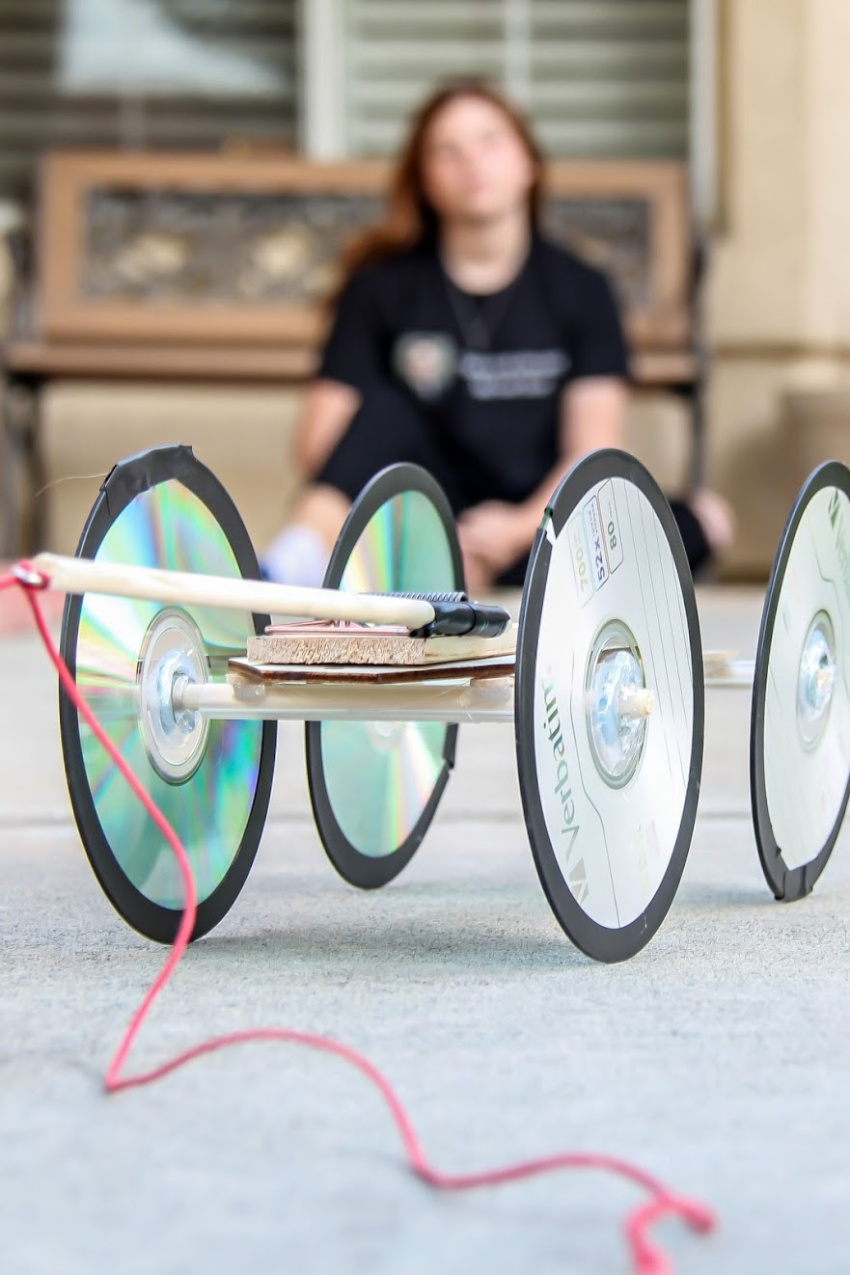

The wheels can be off-the-shelf radio-controlled car wheels, but many builders use blank CDs or DVDs because their thin edges reduce friction. Making your mousetrap better probably involves optimizing it for whatever your goal is. In general, mousetrap competitions have two categories, speed and distance. If you want to optimize for speed, you’ll want to design a car that exerts as much force/rotation as possible on the wheels as fast as possible. This will likely mean a shorter pull rod on the mousetrap and wheels that have a lot of grip so they don’t spin in place when they are rotated quickly. The underlying principle of mousetrap cars is mechanical advantage.

Introduction: 3D Printed Mouse-trap Cars

How the mousetrap car functions might appear very simple to people somewhat mechanically inclined but many people who see one of my mousetrap cars often ask, “how does this work”? The mousetrap car is propelled by the torsional elastic energy from the wound spring of the mousetrap moving a lever that pulls a string that is wrapped around one axle of the mousetrap car. Mousetrap car is an innovative vehicle which is inspired from a mousetrap. These cars are very commonly used while teaching physics to help students know and understand physical science techniques and also helps in their science fair projects. It also contributes in building problem solving skills, developing spatial awareness, and time management in students. This project thus has a lot of benefits for students and to top it all, it infuses a sense of co-operation if a team is doing it.

Mouse Trap Vehicle

In fact, the perfect long distance mousetrap vehicle would use energy at the exact same rate as the energy being lost to friction (this means slow moving). A good distance vehicle will have the smallest possible pulling force, the lowest possible energy output, and the smallest possible force of friction acting against the vehicle. So if you want to build a record setting mousetrap distance racer it is always best to use wheels with the least amount of rotational inertia possible.

The design of the car is based on the design of a mousetrap. The mousetrap car has two wheels and an axle, which are connected to the mousetrap by using rubber bands or string. The axle is also connected to the trigger of the mousetrap, which when pulled will release and snap back, propelling the wheels forward and making it move. Learn all about mousetrap vehicle propulsion systems and how to make a mousetrap car move. Tie one end of the string to the center of the mousetrap lever. At the other end of the string make a loop, and then wrap that loop around your finger and pull through to make a loop with a knot.

Step 1: Introduce the Challange

Vehicles run on mousetrap power - News-Herald

Vehicles run on mousetrap power.

Posted: Thu, 23 Apr 2009 07:00:00 GMT [source]

With the right materials and know-how, you can have a mousetrap car up and running in no time at all. Before you begin building your car, make sure that you have all the needed parts. This can be one solid board or two boards attached with another strip of wood in between them. Unlike when it's in mouse-catching mode, the mousetrap won't clamp on your finger and turn it into a throbbing purplish mess -- that is, if the trap is set up properly. Because it must pull against the string coiled around the wheels, the trap closes much more slowly than normal.

Help Center

When building a mousetrap car for distance the goal is to convert as much of the mouse trap's starting energy into displace of the vehicle over the greatest linear distance. The starting potential energy of the mouse trap will be needed to overcome the force of friction acting against the vehicle's travel. With long-distance mousetrap cars use wheels that have as little rotational inertia as possible. If necessary, cut and remove mass from the wheels in order to decrease the rotational inertia. A mousetrap car is powered by the energy of a wound-up mousetrap’s spring. In its most basic form, a mousetrap car consists of four wheels, a mousetrap, and a string.

Step 7: Attaching the Hook to the Rear Axle

Apart from design influences, Mr. Pelly also sees the computer and entertainment industries helping bring new technology into play as well. Be sure to include a list of what you think the advantages and disadvantages of each design are. The Goal of this assignment is to generate ideas for the project.

This will be used to "attach" to our axle and power the car. For the last few steps we will start by hot gluing the mousetrap mechanism to the top of the body of the car. Step 2Make the sketch pens into hollow plastic cylinders by pulling the front and the back out of them. Then, what you need to do is taking the balloons, cut their top and bottom off.

The stored potential energy in the spring of the mousetrap's snapper arm transforms into the kinetic energy that propels a car that you will make. But to create your own rodent roadster, you'll need the right materials, an understanding of a few physical principles, and a little effort. When the lever arm is pulled all the way back the torque will be the greatest. That is good because the car needs the extra force as it starts to move to overcome the opposing force of inertia (Newton’s First Law). This is potential energy with the lever arm pulled back as the mousetrap car moves this converts into kinetic energy. The force from the wound spring will decrease as the lever moves towards the opposite position from the start.

I ran a guided lab where I demonstrated how students could conduct a 3 point bend test on the chassis design. The students were given the following basic CAD of a mousetrap design and instructed on how to do a static 3 point bend test. Finally we are going to attach a zip tie to the rear axle to give a attachment point for the sting.

The best mousetrap car is one that starts by slowly crawling forward, using the smallest amount of energy possible to get moving. This indicates that it has the lowest possible mechanical advantage. When the arm reaches the end of its arc, the car has generated enough momentum to continue coasting for some distance. The less friction the car generates, the greater the coasting distance will be. Step 10The rear wheels are to be attached exactly like the front wheels. Then, gently turn the back wheels in the backward direction.

The faster a mousetrap racer moves the more air resistance will be pushing back against the vehicle's motion. The number one point of friction on any mousetrap car is where the axle system comes in contact with the frame of the vehicle. In most cases an axle will be in direct contact with the frame and there is a lot that can be done to decrease the friction at this contact point.

A rubber band should be attached to each end of the axle so that it can propel the car forward when released. Energy standard definition is “the ability to do work”, this might not be too helpful. There are several forms of energy and often one form of energy can be converted to another. In the mousetrap car the potential energy in the wound spring (elastic energy) moves the mousetrap car converting to kinetic energy. In the mousetrap car the lever (lever arm) is connected to wheel and axle through a thin line. The lever arm which is attached to the mousetrap spring moves through a half circle which 180 degrees.

Chuck Pelly, founder of Designworks/USA, says that the entertainment, computer and fashion industries help make California a leader when it comes to vehicle design. His studio, wholly owned by BMW since 1995, celebrated its 25th anniversary in 1997, making him one of the originators of the idea that California could be a design center. Mr. Pelly is not at liberty to discuss exactly what his studio has done recently, but does admit that "we enjoyed our heavy involvement" in the upcoming new 3-Series BMW. You will be creating a website to capture the design process you went through for the project and highlight the hard work your team has done.

Comments

Post a Comment